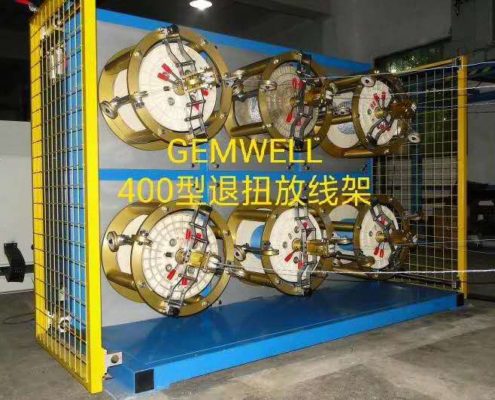

◆Structure: center rotary type.

◆Electro‐magnetic tension control, ensure tension stable.

◆0~100% back twist rate, can set on the line touch screen directly.

◆Safety protection: Alarm and shutdown in case of overload or wire broken.

◆Easy loading & unloading bobbin with quick lock device.

| Model | 300 | 400 | 500 | 630 | 800 | 1000 |

| Wire

OD |

φ0.4mm

φ1.2mm |

φ0.6mm

φ2.5mm |

φ1.2mm

φ4.5mm |

φ2.0mm

φ6.0mm |

φ3mm

φ12mm |

φ4mm

φ18mm |

| Max Speed | 800 rpm | 600 rpm | 400 rpm | 350 rpm | 300 rpm | 250 rpm |

| Loading capacity | 30kg | 60kg | 120kg | 300kg | 500kg | 1000kg |

| Tension range | 100g

500g |

300g

1500g |

1000g

3000g |

2000g

8000g |

4000g

20kg |

8000g

50kg |

| Tension

fluctuation |

50g | 100g | 200g | 400g | 800g | 1500g |

| Loading method | manual | manual | electric | electric | Electric-

hydraulic |

Electric-

hydraulic |

| Brake | electric | electric | electric | electric | Electric-

pneumatic |

Electric-

pneumatic |

Taping and Stranding line

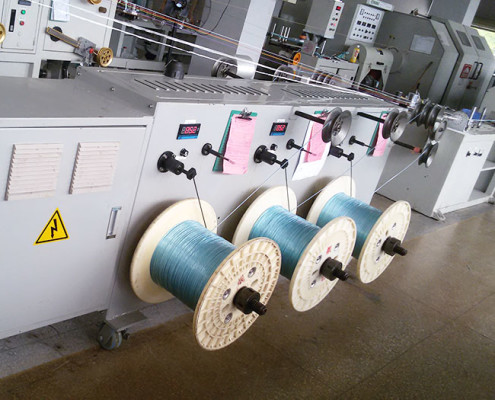

Process: Back-twist payoff, multy shaft payoff, pre-twisting, concentric taping, stranding.

Application for the production of Rorbet cable, signal cable, date cable, instrument cable, medical equipment cable etc.

Single twist stranding line, with multi backtwist payoff, for producing robert cable flexible cable instrument cable.

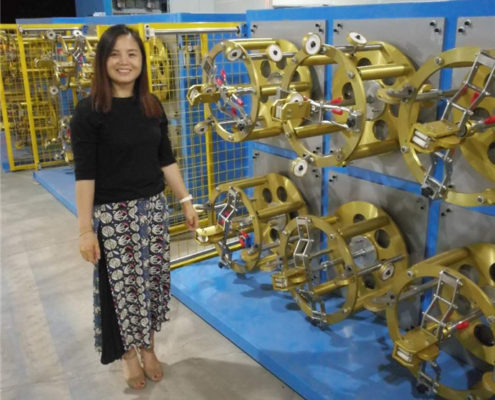

loading & uploading bobbin for back twist payoff

This part for download file.

Single Twist Cabling Lines

For the production of:

Communication cables with excellent electrical characteristics, should be match the stringent requirements for high-bandwidth system, such as USB, HDMI, DP, MHL, DVI, LAN cables etc.

Description:

● Payoff DIN400-630

● Horizontal double layer taping machine

● Dual wheel capstan

● Take up DIN400-630

● PLC control system with color touch screen

Advanced function (Optional):

1. Motorized payoff

2. Longitudinal or concentric taping head

1. HMI + PLC control system, twisting pitch, production, line speed set on touch screen, alarm and recipe system, easy operation.

2. Wide range for cabling cables, special for LAN cable, USB date cable, control, measuring etc. Equipped with concentric or longitudinal taping unit for shielding purpose.

3. Pitch accurate, electronic tracking pitch, driven via differential unit, pitch can be constant when speed accelerating or decelerating.

4. Self-traversing, traversing and bobbin-holding devices from one complete unit. Traversing unit moves on railway guides via motor, superior quality for twisted cable electrical performance.

| Model | ST630 | ST800 | ST1000 | ST1250 |

| Inlet insulation wire (mm) | Φ1.0-4.0 | Φ1.5-6.0 | Φ2.5-8.0 | Φ5-10 |

| Max finished cable dia.

(mm) |

Φ3-10 | Φ3-14 | Φ3-20 | Φ10-30 |

| Pitch range (mm) | 20-250 | 20-250 | 20-250 | 20-250 |

| Rotation speed (rpm) | MAX 900 | MAX 750 | MAX 600 | MAX 450 |

| Take-up reel (mm) | 630 | 800 | 1000 | 1250 |

| Take-up reel loading | Electro-Hydraulic lifting | |||

| Traversing | Separated AC motor drive, moving on railway guide. | |||

| Control system | HMI + PLC automatic control system | |||

Taping and Stranding line

Process: Back-twist payoff, multy shaft payoff, pre-twisting, concentric taping, stranding.

Application for the production of Rorbet cable, signal cable, date cable, instrument cable, medical equipment cable etc.

Know more please feel free to contact us:

Selina Mobile | Whatsapp | Wechat: +86-137 9061 9167

Email: gemwellsheng@163.com; selina@gemwellgd.com

This part for download file.

Contact Info

LATEST PRODUCTS

- Vertical Dual Backtwist PayoffOctober 24, 2019 - 1:54 pm

- Electric Pitch Bow Double Twist Machine with Twin Back-twist PayoffDecember 4, 2018 - 8:05 pm

- Rotate Frame Single TwistOctober 10, 2018 - 2:55 pm

Latest News

- Gemwell in 2023 Wire ChinaSeptember 13, 2023 - 8:23 pm

- Welcome to virtual visit Gemwell new factory in Jiangsu provinceMay 6, 2022 - 10:52 am

- Gemwell expand manufacturing in new factoryAugust 24, 2021 - 12:10 pm